Designed with durability and practicality at its core, the KW-2 twin keg washer addresses the increasing demand for in-house keg washing solutions among breweries. The system offers an affordable and high-quality alternative for brewers considering investments in stainless steel kegs amidst the limited availability of reusable kegs on a contract basis.

Rated for cleaning over 30 kegs per hour, the KW-2 represents a high throughput and cost-effective option, offering exceptional value for breweries investing in in-house keg washing solutions.

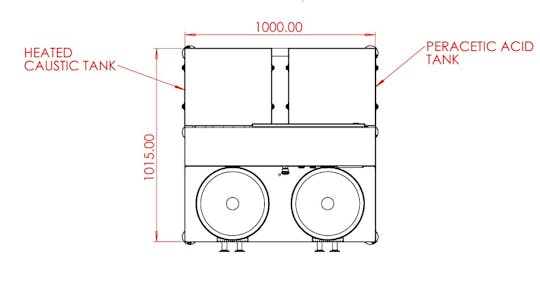

The KW-2 utilises standard keg couplers, available in all industry standard fittings, connected via 1” brewery hoses with swaged tri-clamp fittings for easy setup. The operator simply connects the coupler to the keg, before inverting it and placing it on the machine table - a fast and user-friendly solution. The built-in caustic tank includes a heating element, temperature sensor, and level sensor, with adjustable temperature control via a Siemens touch screen HMI.