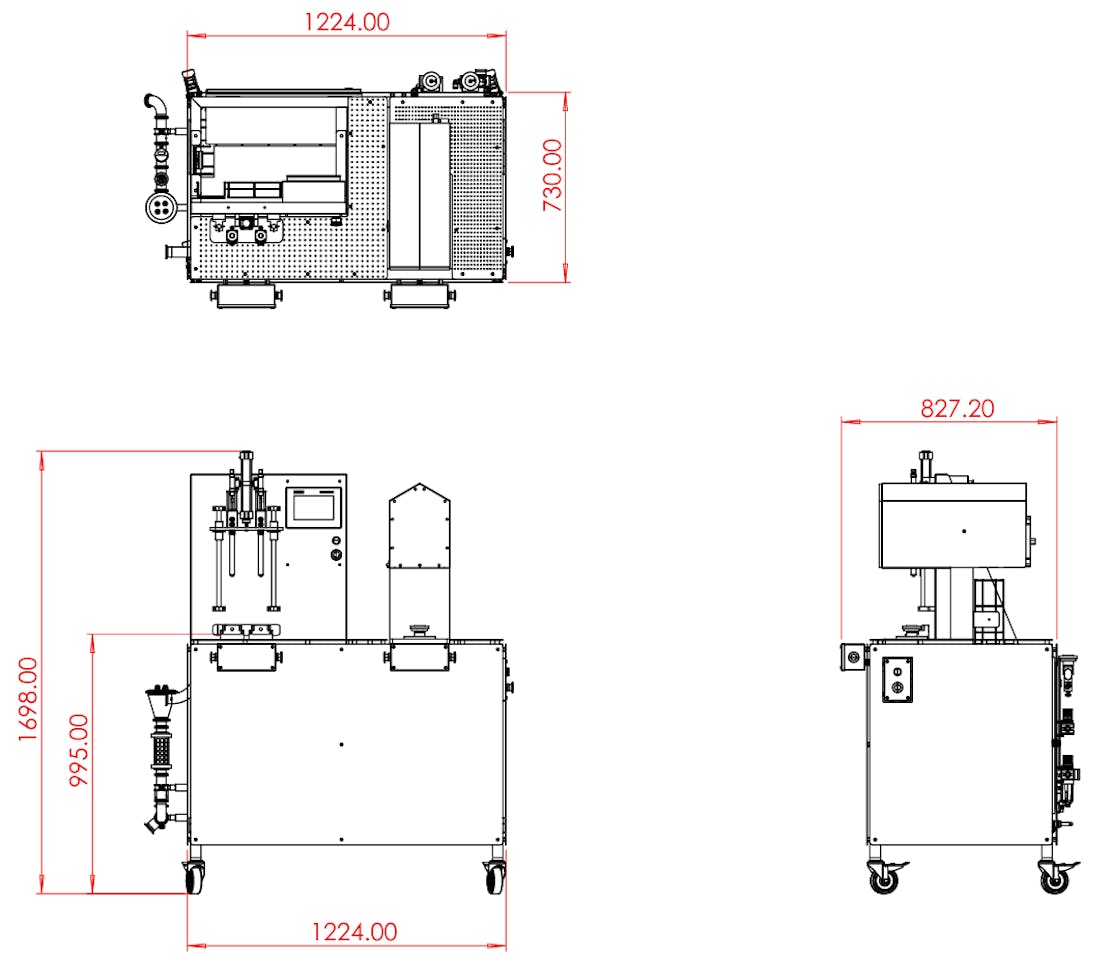

The CF10 is a compact semi-automatic machine for filling and closing aluminium standard, sleek or slim beer and beverage cans. It comprises a two head filling gantry with pre-purge and post-fill gas injection and a single head motor driven mechanical can seamer. The machine is manufactured fully from food grade 304 and 440C stainless steel and food grade plastic, with the most resistant grade 316 stainless steel used in contact areas.

Filling is fully adjustable by time, optimised by the inbuilt brite tank pressure monitoring system. This delivers extremely consistent filling to +/- 2ml. The CF10 seamer features the same high quality seaming mechanism as on all our machines, and is suitable for 150-568ml cans. The mechanism is purely mechanical, meaning the quality of the seam is not reliant on air flow to pneumatic cylinders. The seamer also has accurate base pressure adjustment through the form of a mechanical spring. This is critical to the correct formation of the body hook and overall shape of the double seam. Both modules are operated by push button control, for both ease of operation and operator safety.