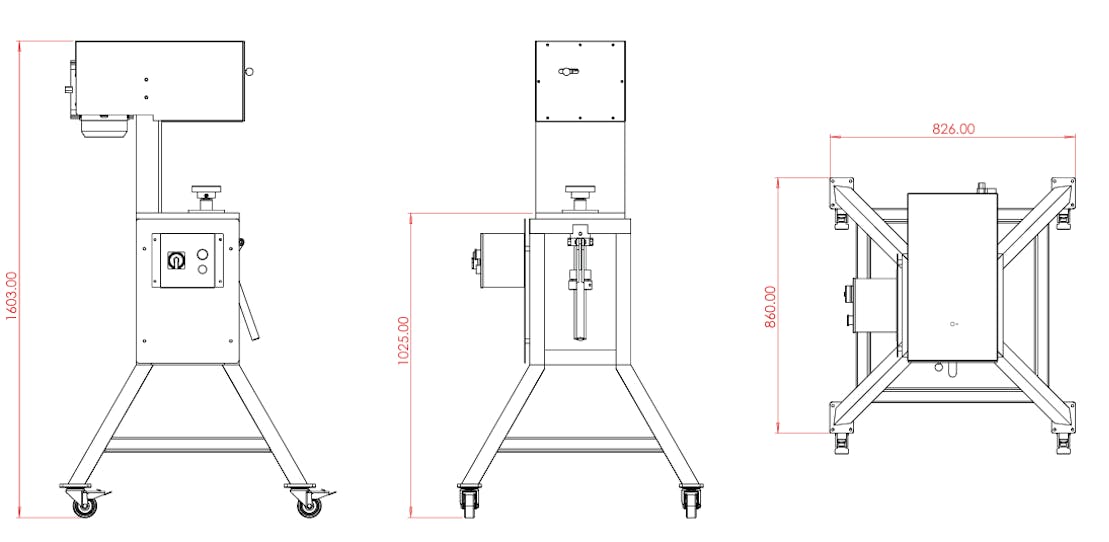

The 10M Can Seamer is a single head, manually actuated can seamer. Manufactured from 316 stainless steel, the 10M is a robust and reliable solution for can seaming in laboratory, pilot plant and low volume production environments. Suitable for seaming tinplate, aluminium, paperboard or plastic cans, the 10M is extremely versatile in use and the premier option for a complete range of applications. A high number (13) of 1st Op revolutions mean even the most lightweight ends can be closed with optimal double seam formation. The seaming operation is motor driven and manually triggered using a lever. The 10M has the same mechanical components as a high-speed seamer but in a smaller frame, to ensure the highest quality commercial seam integrity.

The lifter mechanism has an adjustable mechanical spring and is raised against a repeatable dead stop, allowing full and easy setting for a repeatable body hook parameter. Changeover to different can heights is extremely easy using the height adjustable lifter shaft, taking just a couple of minutes using the pin height gauges. Can diameter changeovers take just 10 minutes from start to finish