Protecting Potency and Purity

Cannabis products are sensitive. Metal packaging acts as a strong barrier against the elements that degrade them: oxygen, light, and moisture. These factors can reduce the potency of THC and CBD and diminish the unique terpene profiles that give strains their distinct aromas and effects. Unlike some plastics, metal is impermeable, ensuring cannabinoids and terpenes remain stable.

Metal's opacity provides 100% light protection, especially against damaging UV rays, keeping the product as fresh and potent as when it was packaged. Its airtight and moisture-proof seal also prevents cannabis from drying out or developing mould, extending shelf life and ensuring a consistent user experience.

These benefits are significantly amplified by advanced sealing techniques. Vacuum seaming, for example, removes air from the can before sealing, creating a near-oxygen-free environment. This dramatically slows down oxidation processes. Flushing cans with Nitrogen before sealing displaces any remaining oxygen with an inert gas. Nitrogen doesn't react with cannabis compounds, ensuring the product remains incredibly stable and potent for extended periods.

Sustainability and Brand Appeal

In today's environmentally conscious market, packaging sustainability is a key factor. Metal packaging, particularly steel and aluminium, has a high recyclability rate. Both materials can be recycled infinitely without losing quality, contributing to a circular economy. Highlighting this commitment to sustainability can strongly resonate with eco-conscious consumers.

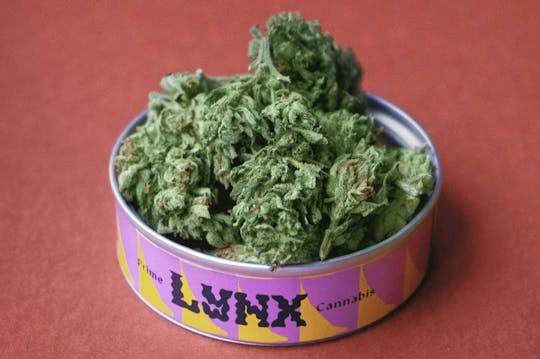

Beyond functionality, metal packaging offers great opportunities for brand differentiation. The smooth, durable surface of a metal tin allows for high-quality printing and embossing, allowing brands to create visually appealing and tactile packaging. In a competitive market, premium metal packaging can help a product stand out and build strong brand recognition.

Our Seamers

Whether you need a compact semi-automatic seamer like our 10VG suitable for smaller production volumes of up to 500 cans per hour, or a fully automatic machine rated for 2000+ cans per hour, Innovus Engineering will be able to offer a suitable model, complete with vacuum and Nitrogen flushing technology and all the competitive advantages those technologies bring.