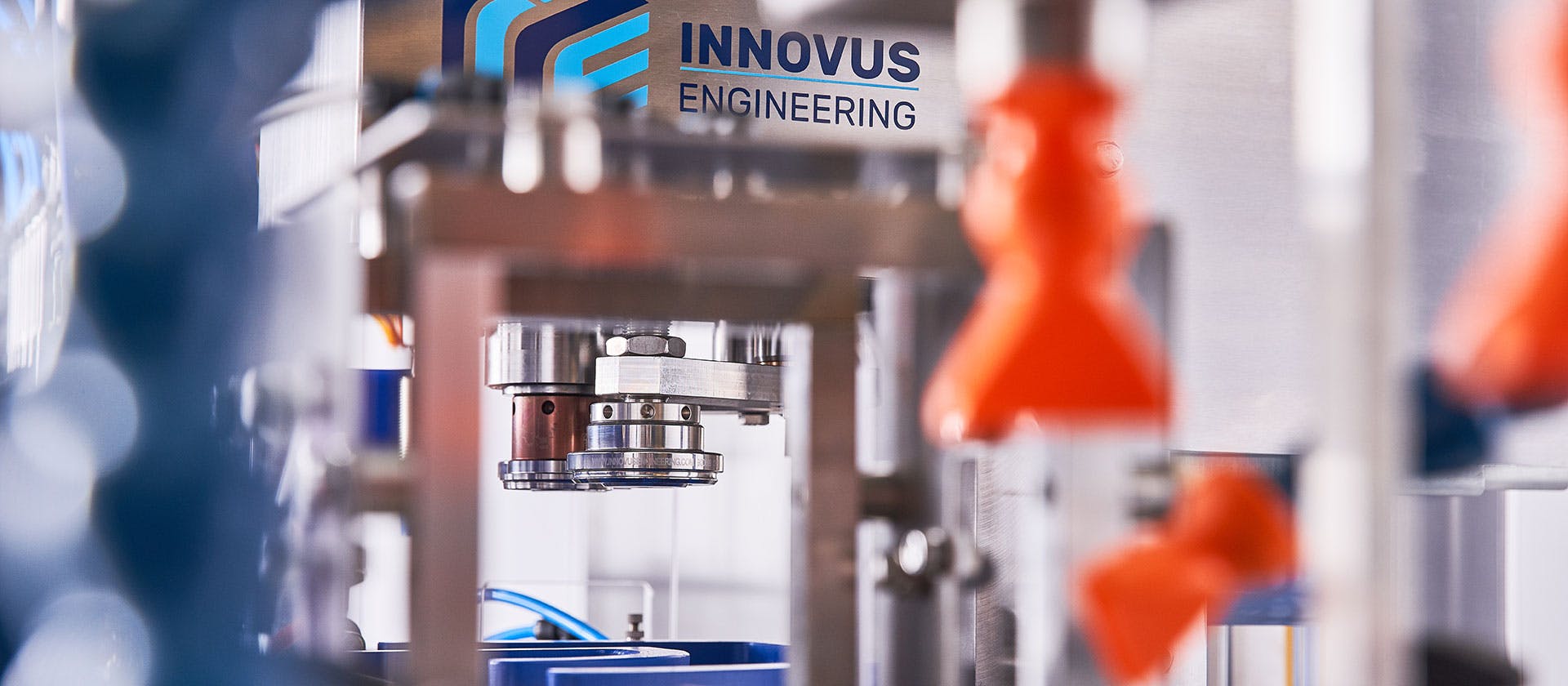

Pioneers in automated production

Innovus Engineering is a highly specialised engineering business offering industry leading can filling & seaming machinery.

Headquartered in West Sussex, all design & manufacturing is in-house, utilising premium materials & components to deliver extremely high technical specification & build quality across all product categories. Trusted by globally recognised manufacturing businesses, we aim to provide unrivalled performance & quality for small & medium scale applications.

Modified Atmosphere

Vacuum seaming & Nitrogen flushing functionality is available throughout our product range & to high specification, delivering residual oxygen levels of less than 0.5%.

Hygienic Design

Our machinery is designed to European Hygienic Engineering & Design Group (EHEDG) principles & thus is suitable for the strictest safety requirement applications.

Innovation

We strive to always push the boundaries of performance through innovative design & material choices, delivering lasting value for our customers.

Products

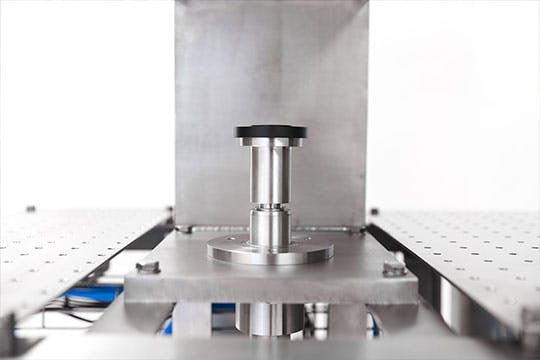

Vacuum & Gassing

Crucial for preserving the quality of your product & meeting safety guidelines, our modified atmosphere seamers deliver high performance & peace of mind at all scales...

Beverage Canning

Our beverage canning machines range from 500 to 4000 cans per hour - ideal for small & medium sized producers of all beverage types...

Automatic Seamers

For higher volume requirements our automatic seamers deliver extreme accuracy with increased automation & efficiency across all applications...

Semi-Automatic

For smaller scale applications our semi-automatic seamers deliver unrivalled performance at lower capacity, with full modified atmosphere functionality available...

Applications

Milk Powder

We offer several seamers designed specifically for milk powder applications featuring hygienic design & exemplary vacuum performance where product safety is paramount...

Explore

Ambient Food

From semi-automatic single can seamers through to fully automatic vacuum & gassing machines, we have the solution for your product to preserve freshness & extend shelf-life...

Explore

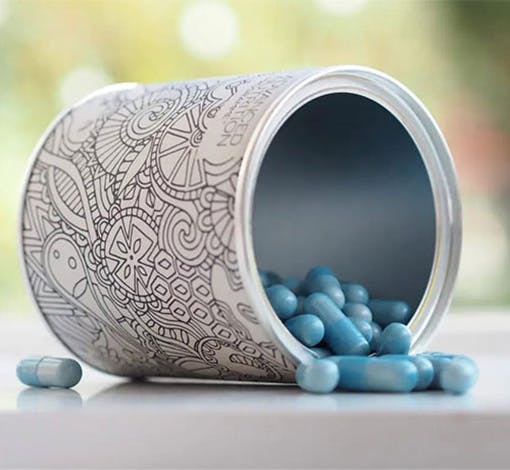

Pharmaceutical

Stand out on the shelf whilst ensuring the safe preservation of your product, with metal, cardboard & polymer packaging all suitable for use with our seamers...

ExploreCase Studies

Ornua Foods

Ornua Foods solve their large can diameter challenge with help from Innovus Engineering and the 10VGT

Read More